TOTAL CUSTOMIZATION CAPABILITY

Complete in-house production from design to final assembly for over 30 years of experience.

- Comprehensive customization solutions

- Full integration service

- Diverse metallic material options

- Regulatory testing and validation

- End-to-end quality assurance

MATERIALS AND DEVELOPMENT

Specialized in titanium and advanced metals processing. Core materials and competencies are:

- Titanium fabrication and forming

- Hardened precipitated types 465 and 630

- Dual-phase stainless steel 2205

- ISO4210-certified tubing

- Advanced material testing capabilities

- Custom material solutions

MANUFACTURING ASSESSMENT

Technical evaluation and risk mitigation services for your path to sucess.

- Design feasibility analysis

- Manufacturing process planning

- Technical specification review

- Risk assessment

- Production optimization

- Iterative design collaboration

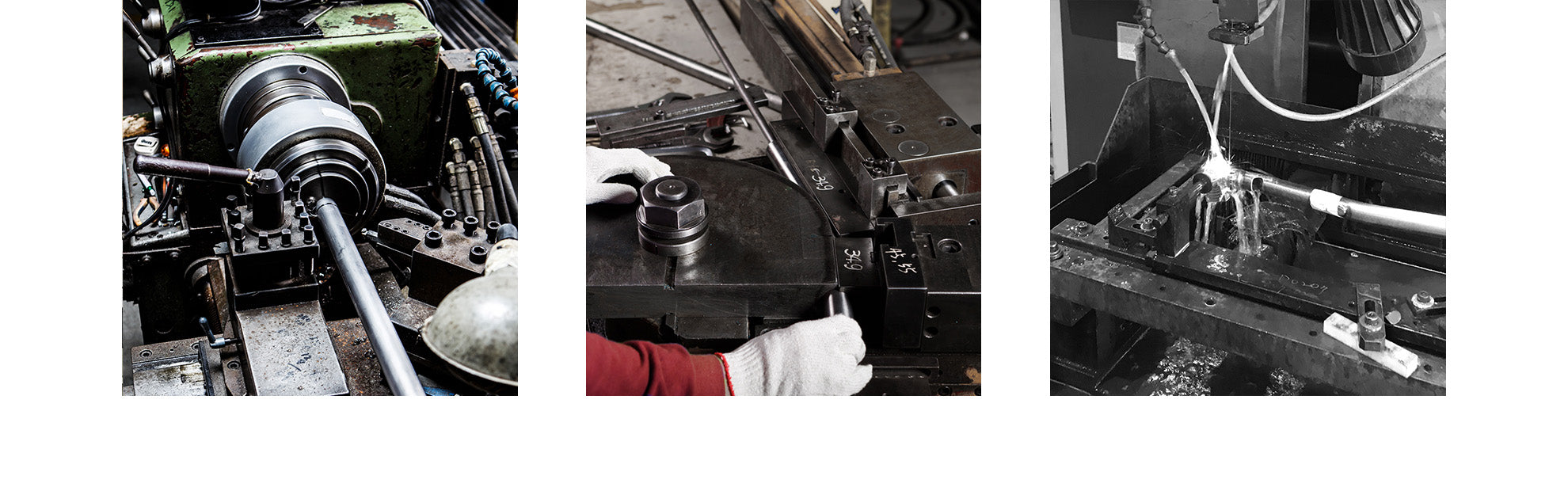

35,000 ft² PRODUCTION FACILITIES

Precision manufacturing with in-house control. Key manufacturing capabilities include:

- 5-axis CNC machining (±0.001" tolerance)

- Heat treatment and stress relief

- 200-ton hydraulic forging

- Metal 3D prototyping (325x325x400mm)

- Precision welding

- Custom fixture fabrication

- 90% in-house production

- Experienced technical team